- Home

- Our Abilities

OUR ABILITIES

Lithium-ion Battery Separator

: a world of constant innovation

Cost reduction, technological development, and the global trend of eco-friendly energy transition are tasks to be pursued continuously.

ST YOUNGWON is enhancing cost competitiveness by offering one-stop consulting services that support every stage, from concept and design to manufacturing and mass production of separators.

Lithium-ion Battery Separator

: a world of constant innovation

Cost reduction, technological development, and the global trend of eco-friendly energy transition are tasks to be pursued continuously.

ST YOUNGWON is enhancing cost competitiveness by offering one-stop consulting services that support every stage, from concept and design to manufacturing and mass production of separators.

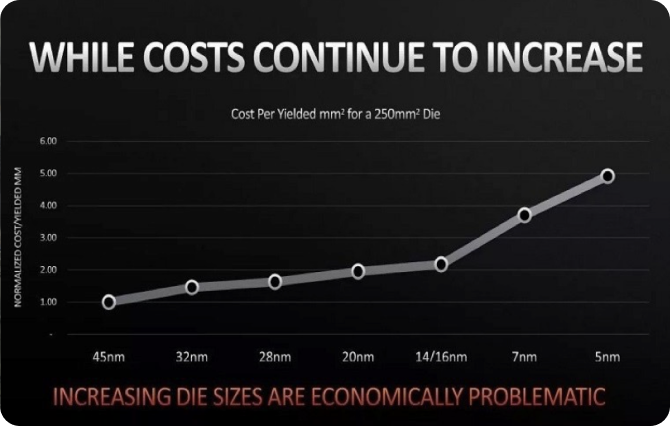

Innovative Design for Cost Reduction

ST YOUNGWON is collaborating with customers from the initial stage of facility design to reduce design lead time and minimize problems that may arise when producing separators.

Through 3D simulation, functional elements of the facility can be predicted and thus the performance and stability of the separator facility can be greatly improved.

Given the high CAPEX in separator business, ST YOUNGWON offers various design options – from basic to custom – to help customers optimize costs while meeting their needs.

ST YOUNGWON is collaborating with customers from the initial stage of facility design to reduce design lead time and minimize problems that may arise when producing separators.

Through 3D simulation, functional elements of the facility can be predicted and thus the performance and stability of the separator facility can be greatly improved.

Given the high CAPEX in separator business, ST YOUNGWON offers various design options – from basic to custom – to help customers optimize costs while meeting their needs.

From Plant Design To Mass Production

1Plant Conceptualizing Stage

It is a discussion stage on the entire plant concept that accompanies the beginning of the business, and it derives optimized concept specifications.

- Consultation on the entire project schedule

- Consultation on the architectural structure and shape of workplaces

- Consultation on area-specific capacity

- Create efficient facility layout drawings

2Facility Conceptualizing Stage

This is for checking the concept specifications for each part on the supply range of the wet separator facility.

- Setting the facility supply range

- Discussing demanded concept

- Working out concept drawings

- Selecting facility specifications

3Contracting Stage

Quotation is provided and contracts are executed, based on specifications that meet the needs

- Facility supply agreement

- Consulting agreement

- Solution agreement

- Maintenance agreement

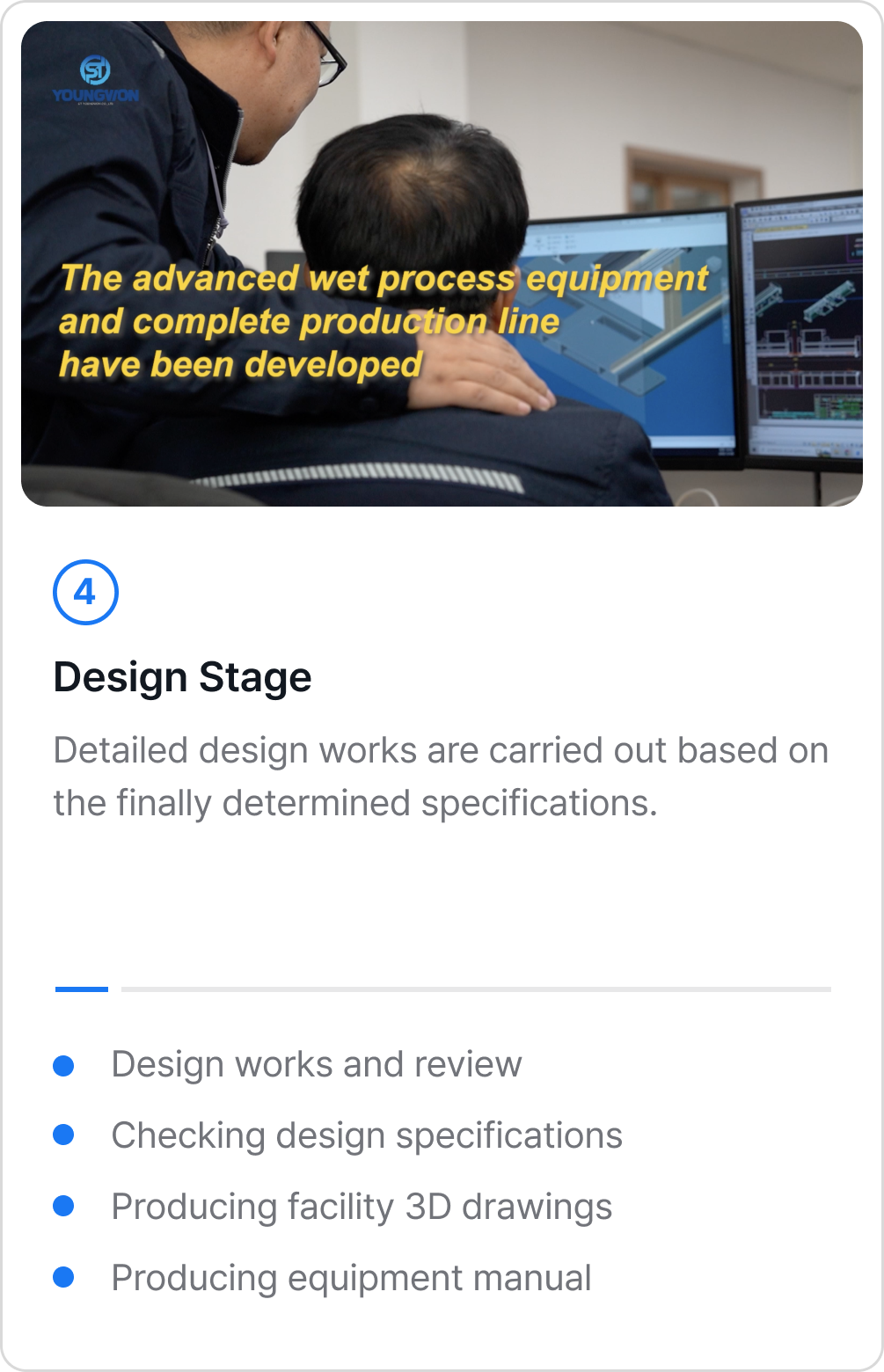

4Design Stage

Detailed design works are carried out based on the finally determined specifications.

- Design works and review

- Checking design specifications

- Producing facility 3D drawings

- Producing equipment manual

5Workplace Site Construction Stage

Based on the concept plan of workplace, consulting on the construction of building structures is conducted.

- Checking detailed construction schedule

- Inspecting building facilities and structures

- Securing all supplies in the facility layout

- Preparing for framing work and installation seating

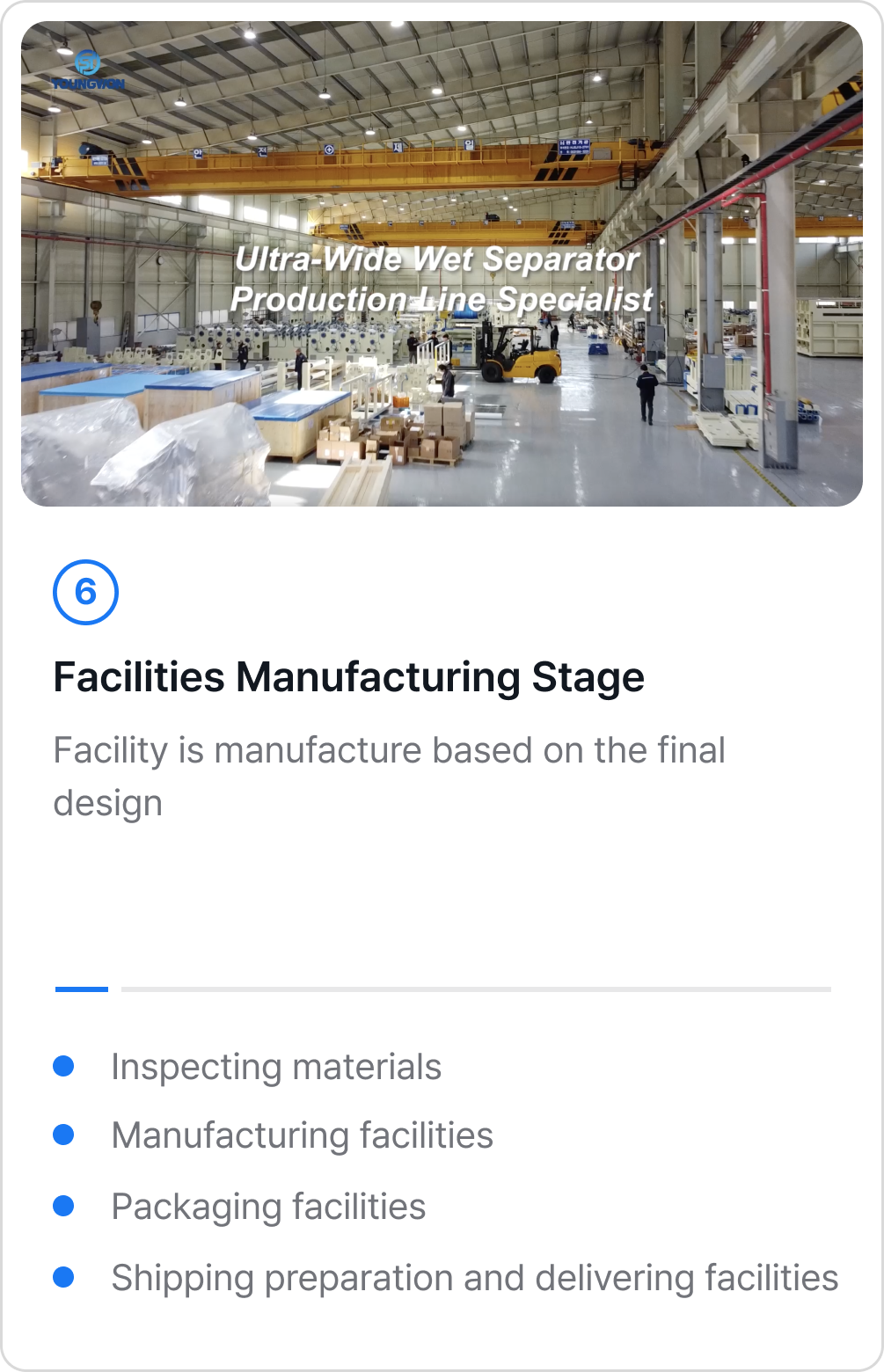

6Facilities Manufacturing Stage

Facility is manufacture based on the final design

- Inspecting materials

- Manufacturing facilities

- Packaging facilities

- Shipping preparation and delivering facilities

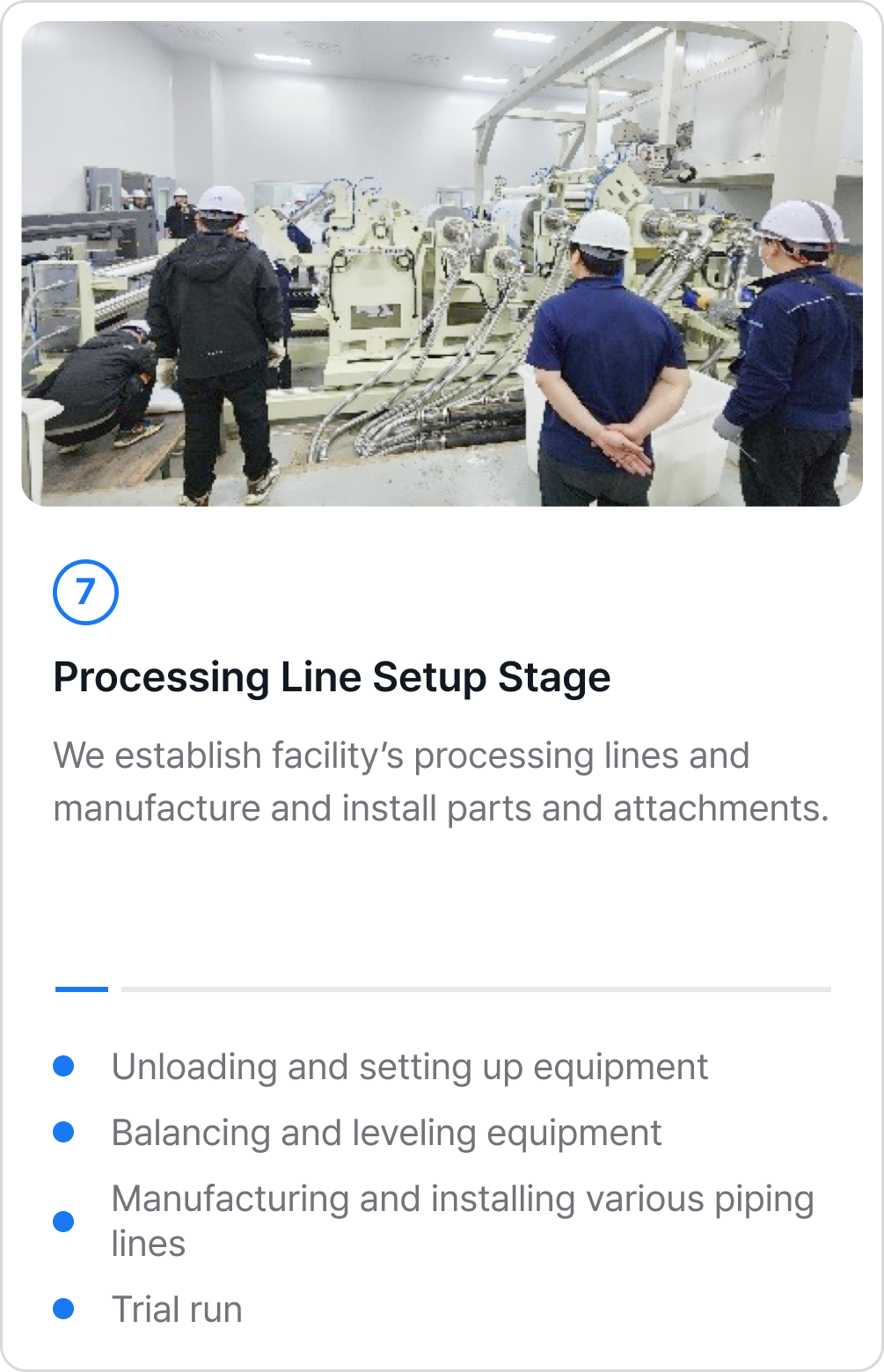

7Processing Line Setup Stage

We establish facility’s processing lines and manufacture and install parts and attachments.

- Unloading and setting up equipment

- Balancing and leveling equipment

- Manufacturing and installing various piping lines

- Trial run

8Production Lines Stabilization Stage

We provide various solutions and support training on process operation so that the production line reaches the safety stage.

- Process control technical support

- Facilities upgrade support

- Process operation management system support

- Quality control technical support

9Initial Mass Production and Completion Stage

We perform the project completion procedure after the initial mass production.

- Pilot production inspection

- Transferring processing technology

- Providing equipment and electricity manual

- Project Completion Report

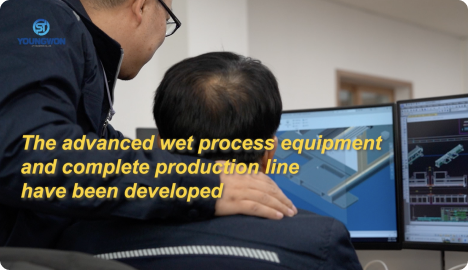

Customized Solution

ST YOUNGWON’s "customized solution" presents practical know-how on "how to do", accumulated from experience through one-stop consulting covering from new workplace concept to mass production stabilization.

Process Control Technical Support

It supports production technology required for process control.

It is a solution that helps maintain stable productivity by improving efficient staffing and maintenance management capabilities required for facility operation.

Facilities Upgrade Support

It supports facility upgrades designed for customer convenience and functionality.

It is a solution that increases the convenience and performance of facilities by supporting user-centered facility upgrades.

Supporting Production Management System

It establishes and provides operational systems required for facility operation

It is an MES and AI technology business support solution that quantifies cost reduction and yield management with certain indicators by establishing production management process for efficient process operation.

Quality Control Technical Support

We establish quality standards ensuring continuous implementation of optimized quality.

It is a solution that conducts on-site customized training on the ability to determine product quality and inspection items.

Customized Solution

ST YOUNGWON에서 제공하는 '맞춤형 솔루션'은 공장 콘셉트부터 양산 안정화까지

원-스톱 컨설팅을 바탕으로 당사의 축적된 실무 노하우와 전문성을 지원합니다.

ST YOUNGWON’s "customized solution" presents practical know-how on "how to do", accumulated from experience through one-stop consulting covering from new workplace concept to mass production stabilization.

공정관리 기술 지원

공정관리에 필요한 생산기술을 지원합니다.

설비 운전에 필요한 효율적인 인원배치와 유지보수 관리 능력을 향상시켜

안정적인 생산성을 유지하도록 지원하는 솔루션 입니다.

설비 업그레이드 지원

고객 중심의 편의성과 성능에 대한 설비 업그레이드를 지원합니다.

사용자 중심의 설비 업그레이드를 지원함으로써

설비의 편의성과 성능을 높이는 솔루션입니다.

공정운영 관리체계 지원

공정운영에 필요한 관리 운영체계를 수립하여 제공합니다.

효율적인 공정운영을 위한 프로세스 수립하여 cost 절감과 수율 관리를

지표로 수치화 시키는 MES 와 AI 기술 업무지원 솔루션입니다.

품질관리 기술 지원

품질관리 기술 지원

사용자 중심의 설비 업그레이드를 지원함으로써

설비의 편의성과 성능을 높이는 솔루션입니다.

Process Control Technical Support

It supports production technology required for process control.

It is a solution that helps maintain stable productivity by improving efficient staffing and maintenance management capabilities required for facility operation.

Facilities Upgrade Support

It supports facility upgrades designed for customer convenience and functionality.

It is a solution that increases the convenience and performance of facilities by supporting user-centered facility upgrades.

Supporting Production Management System

It establishes and provides operational systems required for facility operation

It is an MES and AI technology business support solution that quantifies cost reduction and yield management with certain indicators by establishing production management process for efficient process operation.

Quality Control Technical Support

We establish quality standards ensuring continuous implementation of optimized quality.

It is a solution that conducts on-site customized training on the ability to determine product quality and inspection items.

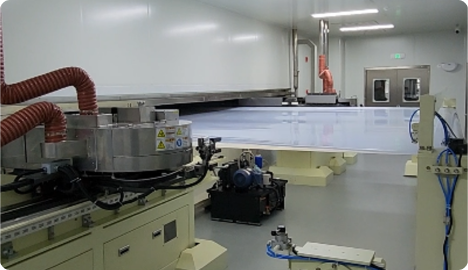

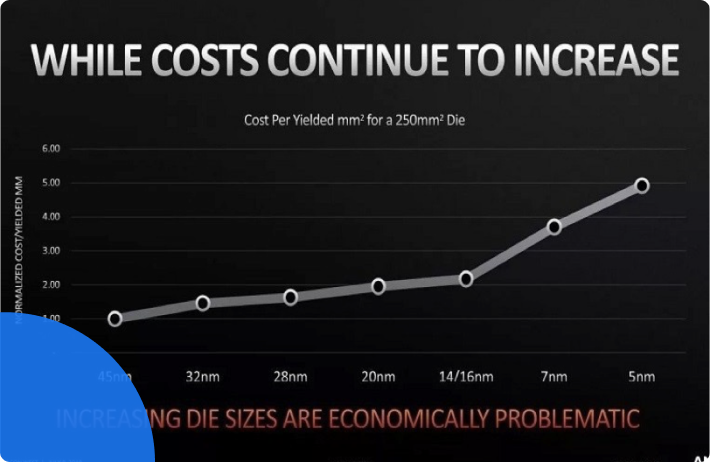

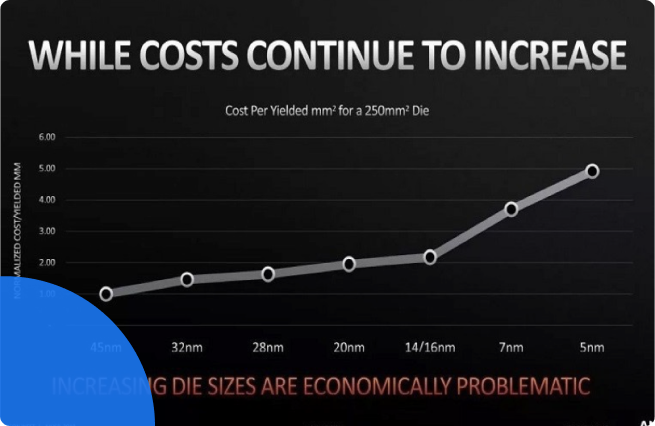

ST YOUNGWON’S Cost Reduction Technology

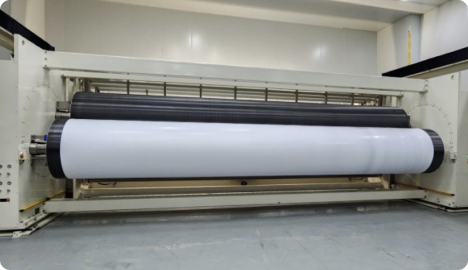

Unsurpassed the world’s first / largest / ultra-wide development - Mass production capacity of 8 meter class ultra-wide separator

Larger and faster production increases product area by more than 60% per hour

Production of the highest quality wet separator

Ensure high-quality product productivity by realizing uniform micropores and thicknesses through the wet process (Separators can be customized with thicknesses ranging from 5µm to 20µm.)

Outstanding Cost-Efficiency

Reduce customers’ opportunity costs with accumulated consulting and design know-how to avoid redundant costs

Development of COATER Process Combination Model (2024)

Significantly simplify the process, reduces production costs by saving space and time, and minimizes quality deviations compared to traditional coating methods

Unsurpassed the world’s first / largest / ultra-wide development - Mass production capacity of 8 meter class ultra-wide separator

Larger and faster production increases product area by more than 60% per hour

Production of the highest quality wet separator

Ensure high-quality product productivity by realizing uniform micropores and thicknesses through the wet process (Separators can be customized with thicknesses ranging from 5µm to 20µm.)

Outstanding Cost-Efficiency

Reduce customers’ opportunity costs with accumulated consulting and design know-how to avoid redundant costs

Development of COATER Process Combination Model (2024)

Significantly simplify the process, reduces production costs by saving space and time, and minimizes quality deviations compared to traditional coating methods

ST YOUNGWON is preparing to run toward the future through new material and new technology R&D.

ST YOUNGWON is preparing to run toward the future through new material and new technology R&D.

We continue to invest to secure excellent research personnel and expand facilities.

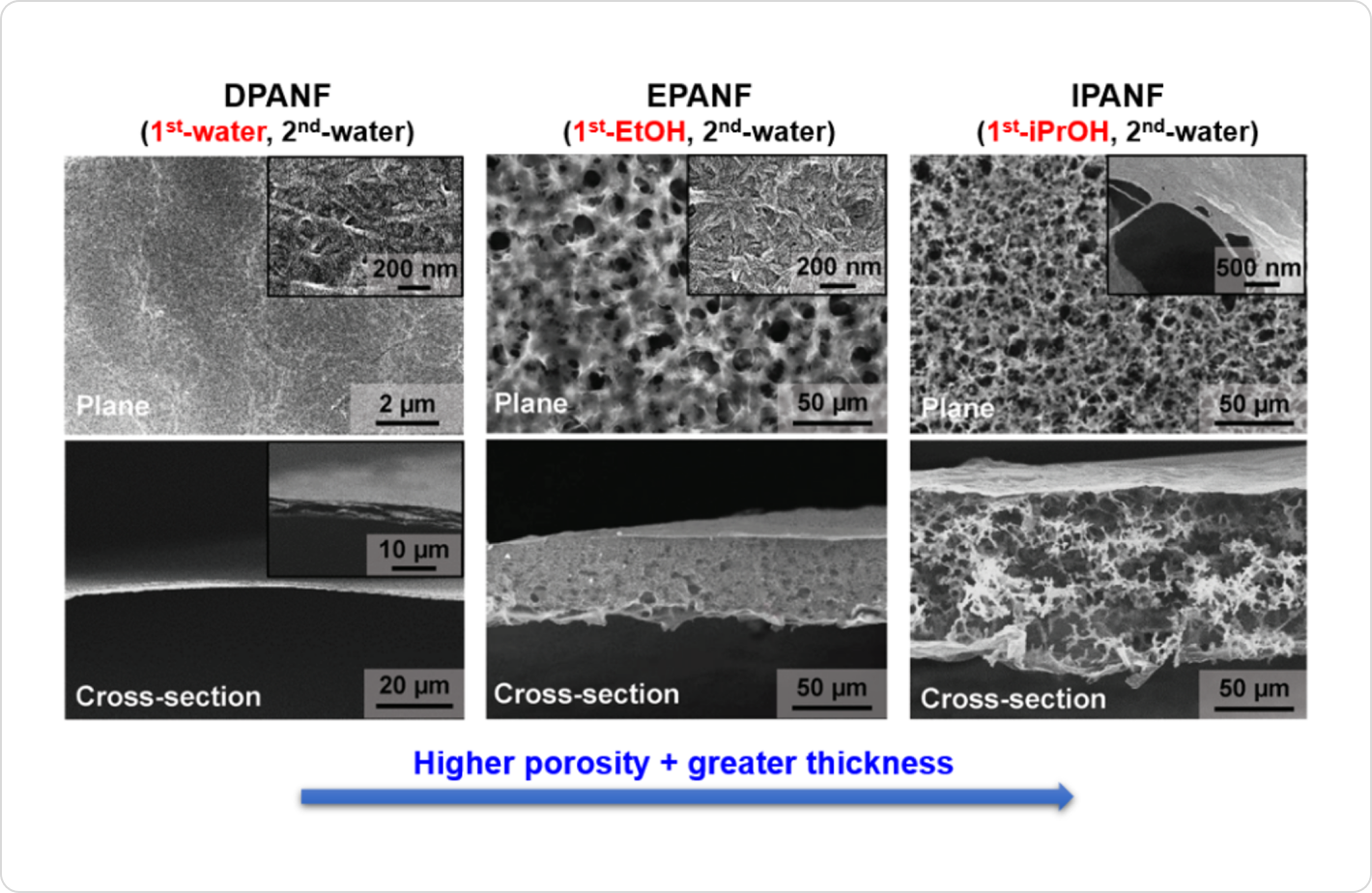

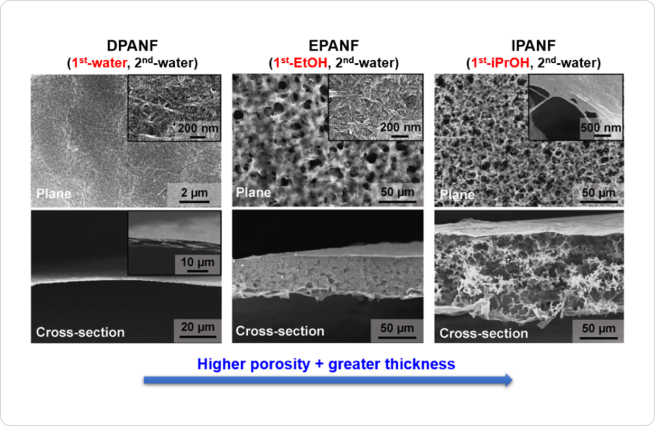

Research and development of alternative solvent materials to replace methylene chloride (MC) for paraffin extraction in separators is currently underway.

It is also striving to increase national competitiveness of Korea by commercializing high-performance aramid separators for next-generation electric vehicle lithium batteries and core manufacturing technologies for future growth engines.

Based on accumulated commercialization technology and eco-friendly energy material research, we will implement sustainable energy solutions to become a leading company in manufacturing core secondary battery material facilities.

We continue to invest to secure excellent research personnel and expand facilities.

Research and development of alternative solvent materials to replace methylene chloride (MC) for paraffin extraction in separators is currently underway.

It is also striving to increase national competitiveness of Korea by commercializing high-performance aramid separators for next-generation electric vehicle lithium batteries and core manufacturing technologies for future growth engines.

Based on accumulated commercialization technology and eco-friendly energy material research, we will implement sustainable energy solutions to become a leading company in manufacturing core secondary battery material facilities.

Major Fields of Research

Eco-friendly Solvent for Wet Separator

Study on eco-friendly extraction solvent substance replacing MC (“Methylene Chloride”)

R&D to lead eco-friendly technology by ensuring environmental protection as well as stability of extraction process

Running R&D test equipment designed for ROLL to ROLL manufacturing technology, to develop high-performance Aramid Separator material

Test operation of dedicated aramid-separator manufacturing equipment using aramid nanofiber-based separator process technology for next-generation electric vehicle Lithium-ion battery with high capacity and fast charging

Development of Aramid Nanocomposite Separator ‘R2R’ Manufacturing Process Technology

Eco-friendly Solvent for Wet Separator

Study on eco-friendly extraction solvent substance replacing MC (“Methylene Chloride”)

R&D to lead eco-friendly technology by ensuring environmental protection as well as stability of extraction process

Running R&D test equipment designed for ROLL to ROLL manufacturing technology, to develop high-performance Aramid Separator material

Test operation of dedicated aramid-separator manufacturing equipment using aramid nanofiber-based separator process technology for next-generation electric vehicle Lithium-ion battery with high capacity and fast charging

Development of Aramid Nanocomposite Separator ‘R2R’ Manufacturing Process Technology

Advancement of Technology

Starting in 2025, ST YOUNGWON's competitiveness will be aimed at securing technological superiority and introducing advanced facilities to strengthen work efficiency, productivity, and stability with AI Smart Plant.

Starting in 2025, ST YOUNGWON's competitiveness will be aimed at securing technological superiority and introducing advanced facilities to strengthen work efficiency, productivity, and stability with AI Smart Plant.